Prevent Water Tank Leaks with Waterbars

Waterbars, also known as waterstops, are essential components in concrete water tanks to prevent water leakage through construction joints. Here’s a detailed look at their use:

1. Purpose

- Prevent Leakage: Waterbars are embedded in concrete to prevent water from passing through construction or expansion joints in water tanks. They are crucial in maintaining the tank’s watertight integrity.

- Structural Integrity: They help maintain the overall structural integrity by ensuring that joints do not become weak points for water ingress.

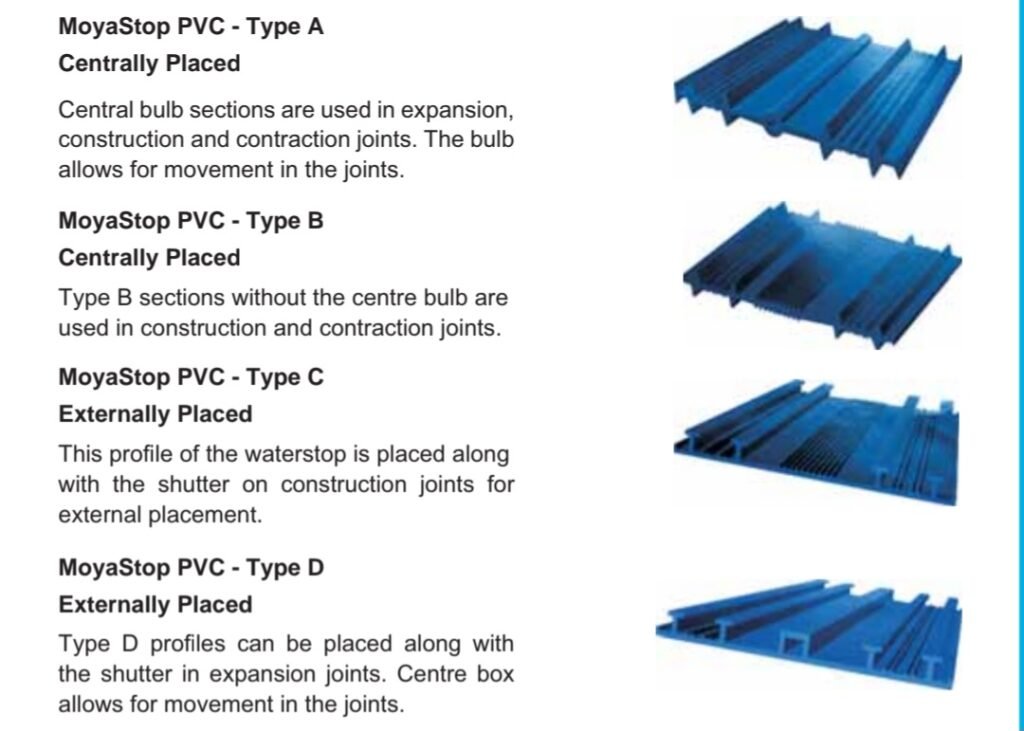

2. Types of Waterbars

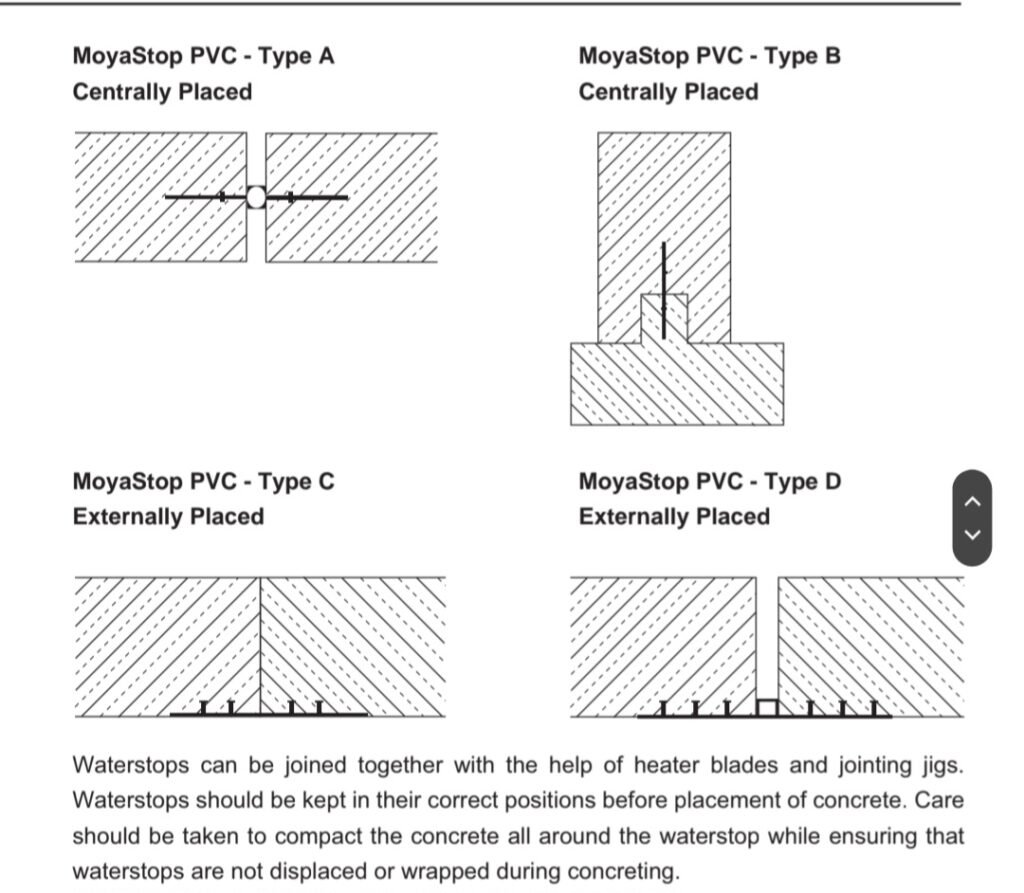

- PVC Waterbars: Made from polyvinyl chloride, these are flexible and can accommodate movements in the concrete structure.

- Rubber Waterbars: Known for their durability and flexibility, these are ideal for use in large concrete structures.

- Metallic Waterbars: Often made of copper or stainless steel, these are used where the structure demands higher resistance to chemicals or extreme conditions.

3. Installation Process

- Placement: Waterbars are positioned in the center of the joint before the concrete is poured. It’s essential to ensure they are securely held in place to prevent shifting during concrete placement.

- Overlap and Sealing: Overlapping sections of waterbars are sealed using heat welding or specific adhesives to ensure continuity.

- Care During Pouring: Concrete must be poured carefully around the waterbars to avoid displacing them. Proper vibration techniques should be used to eliminate air bubbles around the waterbars.

4. Advantages

- Effective Waterproofing: Waterbars are one of the most effective methods for preventing water leakage through construction joints.

- Durability: When properly installed, they provide long-lasting protection against water ingress.

- Versatility: Suitable for various types of concrete structures, including water tanks, dams, basements, and swimming pools.

5. Maintenance

- Regular Inspections: Periodic inspections of the joints where waterbars are installed can help detect any potential issues before they lead to leakage.

- Repair: If a waterbar is damaged, repairs can be done by injecting sealants or replacing the damaged section, depending on the extent of the damage.

6. Considerations

- Proper Design: The choice of waterbar should be based on the type of tank, the movement expected at the joints, and the chemical environment.

- Quality Control: Ensuring that high-quality materials are used and that installation is done by experienced professionals is critical for effectiveness.

Waterbars are an indispensable part of the design and construction of concrete water tanks, ensuring the structure remains leak-free and durable over time.